What Really Happens at a Vinyl Pressing Plant

Vinyl pressing plants matter big time for your record’s sound. When you play a record, you’re not just hearing tunes. You’re hearing what happens because of heat, pressure, and doing things just right. These plants don’t just copy tunes onto plastic – they decide how the music feels, sounds, and lasts.

The pressing starts once the final version is okayed. First, they cut a lacquer disc, basically a blank record, using a lathe. This lacquer has a physical mark of the audio. Then, they send that disc for electroplating, turning it into a metal stamper that can press the grooves into vinyl.

From Stampers to Finished Records: The Pressing Process

The real heavy lifting takes place after the stampers have been prepped. In a hydraulic press, pucks of raw vinyl, or polyvinyl chloride (PVC), are heated and softened, placed between two stampers, and then pressed. The pressed record is cut from excess material, cooled, inspected, and if there is a label on it, the label will be baked into the vinyl at the time of pressing, so no adhesive is needed.

Finally, records are boxed, shrink-wrapped and then sleeved. Temperature, cooling time, pressure, and substrate all impact the quality of the final recording’s sound.

Why Vinyl Pressing Plants Matter

A pressing plant is not just a building or factory to make records, it is often the last point of influence before that record reaches your turntable. Where the plant comes into play is that they are the ones who determine how a record is pressed and how it will sound in your own space. It is important to note that the quality of a record may differ based on the vinyl compound that was used (Virgin or Recycled), condition of the stampers, and the exact calibration of temperature and pressure.

Some pressing plants operate 24/7 and their business often depends on margins and speed of production. Others have slower techniques so they can produce a better sounding record. Others cut corners with QC to make their volume to keep their business afloat. When the pressing plants deliver records that are not right, they deliver surface noise, warped records, off centre spindle holes, even records that skip out of the jacket.

With audiophiles and collectors, the distinct difference between a good pressing and bad pressing can change the whole outcome of what the listening experience is.

Key Players in the Vinyl Industry

Some pressing plants are known for top-tier sound. Others… not so much.

| Plant | Country | Known For |

|---|---|---|

| Optimal Media | Germany | Clean, quiet pressings. Trusted for reissues. |

| GZ Media | Czech Republic | Mass volume. Mixed quality. |

| RTI | USA | Audiophile-grade, used by Mobile Fidelity. |

| Pallas | Germany | High-end, often used for classical and jazz. |

| United Record Pressing | USA | Large scale, some quality issues. |

| Record Industry | Netherlands | Solid quality across indie and pop. |

| Mobineko | Taiwan/UK | Good for short runs and coloured vinyl. |

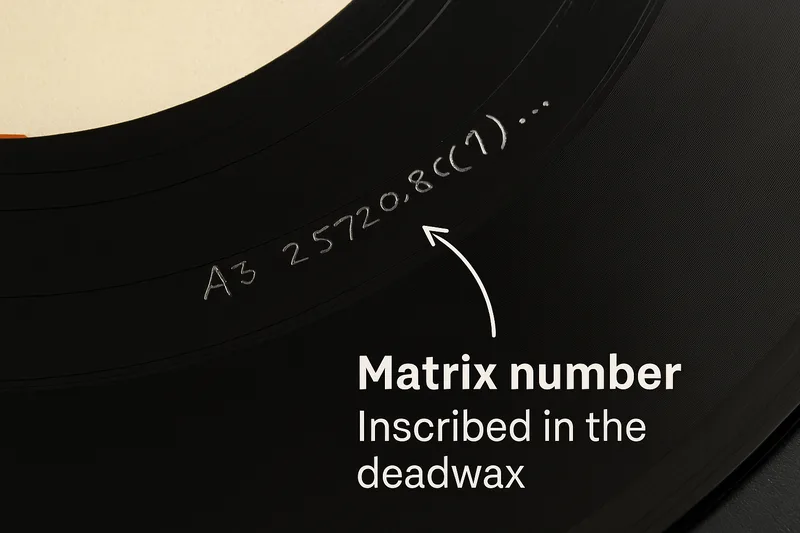

You can sometimes spot the plant by codes in the runout groove (deadwax). Sites like Discogs and Steve Hoffman Forums can help decode them.

Vinyl Compounds: What Goes Into Your Record

The sound quality remains the purest, and the record maintains its durability for the longest time. The environmentally friendly recycled vinyl comes at a lower price, but it produces noises and visual defects which affect its performance. The use of colored vinyl among collectors results in vinyl compound changes because the dyes affect the material composition.

Picture discs suffer greater sound degradation because their production requires placing artwork between two thin layers of transparent vinyl. Modern record labels include information about their vinyl materials through stickers on their products or web pages. A serious music listener should seek out records described as “180g virgin vinyl” or equivalent specifications.

How Vinyl Pressing Plants Handle Coloured Vinyl and Sound

Some plants have learned to handle coloured vinyl well. Others haven’t. Mobineko, for example, is known for neat colour runs. Precision Record Pressing also has a good track record. But in general, black vinyl is still the most stable and reliable.

Vinyl Pressing Defects That Affect Playback Quality

Warping is usually caused by uneven cooling or bad storage, but it can also happen at the plant. Even label misalignment can throw off the stylus, especially on lightweight pressings. These problems aren’t always the plant’s fault, but many are.

Labels like Blue Note’s Tone Poet series or Analogue Productions avoid these issues by working with high-end plants and doing extra rounds of test pressing and quality control.

What the Vinyl Boom Means for Plants

Since the pandemic, vinyl demand has exploded. Pressing plants have scrambled to keep up. Wait times that were once four weeks are now four months. New plants are opening, but not fast enough.

To meet deadlines, some plants push worn-out stampers past their limits or skip test pressing phases entirely. Labels under pressure might settle for less-than-ideal pressings to get stock into stores.

Oddly, a delayed record can be a good sign; it may mean someone slowed down and checked the work.

Behind the Scenes: Visiting a Pressing Plant

I had the chance to visit Press On Vinyl in Middlesbrough. What struck me wasn’t the machinery, but the people.

Press operators examined each disc under lights, scanning for defects before sleeving. A technician showed me how they dial in the steam pressure down to fractions of a degree to get the best groove fill. In one corner, someone realigned label stacks by hand because a batch came in off-centre.

There’s craft in this process. It’s not fully automated. And the people running the presses genuinely care about the outcome. That’s not something you’ll see in a big-box retailer, but it lives in the grooves.

If you ever get the chance to visit any vinyl pressing plants, I would highly recommend it.

Checking Press Quality at Home

- Inspect the deadwax: This runout area should have neat, clean etchings. Sloppy or faint markings might signal poor quality control.

- Check for warps: Lay the record on a flat surface. Even slight curves can affect tracking.

- Test the centre hole: Spin the record without the stylus. A wobble often means it’s off-centre.

- Play the record: Excessive hissing, cracking, or non-fill sounds can point to pressing faults.

Always look up reviews before buying. Forums like r/vinyl on Reddit often flag bad pressings early. Look at the dead wax in the runout area after the final track. Neat etching usually means care went into the process. Hold the record flat to spot warps. Spin it without the stylus to see if the centre hole is true.

If the record hisses or cracks loudly on first play, you might have a dud. And always check forums and communities like r/vinyl for feedback on specific pressings.

Analogue Tech Meets Modern Vinyl. They’re not just making copies, they’re shaping how you hear the music.

Here’s a fun one: a handful of plants have accidentally created “ghost tracks”, faint impressions of music that shouldn’t be there. It’s usually the result of a dirty stamper or poor demolding. Collectors sometimes treat these as rare errors, though they’re technically pressing flaws.

Decoding the Deadwax

Sleeves, Splits, and First Impressions

Why Vinyl Pressing Plants Are Booming Again

A person who values records should begin identifying the production locations of their preferred pressings. Keep track. Share info. The practice will help you stay away from poor-quality records while helping others avoid the same problem. Sound quality depends on mastering and equipment, but these are not the only important factors.

The process begins at the point where grooves receive their formation. The company performs more than duplication because they develop the way music sounds to listeners. The artist‘s intended sound quality experiences changes at every stage of this procedure. Matrix numbers require no obsessive attention from you.

Knowing which plants produce reliable outcomes enables you to select better options. After understanding what to examine and hear, it becomes difficult to remain indifferent.

FAQ

Q. What is a vinyl pressing plant?

A facility where records are physically made using metal stampers and molten vinyl.

Q. How can I tell which plant pressed my record?

Check the runout groove for plant codes. Search Discogs or forums for clues.

Q. Is coloured vinyl lower quality?

Usually, yes. It looks nice, but it can add noise or cause warping.

Q. Are delays in vinyl releases a bad sign?

Not always. Delays often mean better quality control and careful pressing.

Q. What does non-fill mean?

A pressing defect where vinyl doesn’t fill the groove fully, causing tearing sounds.

Vinyl Thoughts: Vinyl pressing plants have more impact than most people think.

They’re not just making copies; they’re shaping how you hear the music. Every part of that process adds or subtracts from what the artist intended.

If you enjoyed this post on “vinyl pressing plants”, you can let me know on the Contact page.

Don’t forget to Bookmark New Vinyl Day for upcoming posts.